No Real-Time Visibility

Can't see what's happening on the shop floor until it's too late. Production delays discovered hours after they start costing you delivery commitments.

Manual production planning, disconnected shop floor systems, and no real-time visibility cost you thousands daily in wasted materials, missed deadlines, and quality issues. FALCON ERP Enterprise Manufacturing gives you complete production control from planning to finished goods.

These aren't just operational hiccups. They're profit killers that compound every single day.

Can't see what's happening on the shop floor until it's too late. Production delays discovered hours after they start costing you delivery commitments.

Manual BOM management leads to ordering errors. Average manufacturer wastes 15-20% of raw materials due to poor planning and tracking.

No way to identify where production slows down. Equipment sits idle while other machines are overloaded, killing overall efficiency.

Can't accurately promise delivery dates. Last-minute rushes, overtime costs, and disappointed customers become the norm.

Quality issues discovered at final inspection instead of during production. Rework and scrap eating 10-15% of production costs.

Equipment breaks unexpectedly halting entire production lines. Emergency repairs cost 3-5x more than planned maintenance.

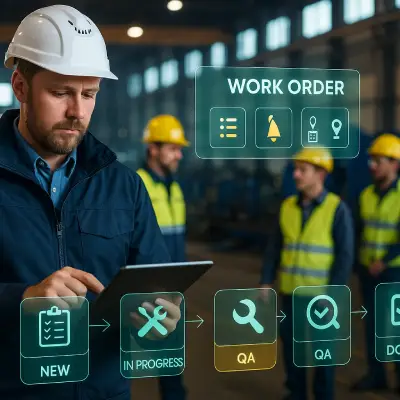

From production planning to finished goods, manage every step with real-time visibility and automated workflows.

Automated production scheduling based on capacity, materials, and delivery dates. Optimize resource allocation and eliminate bottlenecks.

Multi-level BOM management with version control, cost tracking, and automated material requirements. Never order wrong materials again.

Real-time work order tracking, labor recording, and quality checks at every production stage. Complete visibility into what's happening now.

Create, schedule, and track work orders from start to finish. Automated material allocation, routing, and costing for every job.

Real metrics from manufacturers using FALCON Manufacturing

Automated MRP calculates exactly what materials you need, when you need them, and how much to order. No more stockouts or excess inventory. System considers lead times, reorder points, and production schedules.

Track every job through every production stage in real-time. Know exactly where each order is, what's complete, what's in progress, and what's delayed. Complete cost tracking from start to finish.

Built-in quality checkpoints at every production stage. Define inspection criteria, record test results, and catch defects early. Complete traceability from raw materials to finished goods.

Schedule and track equipment maintenance to prevent unexpected breakdowns. Automated maintenance calendars, work order generation, and complete maintenance history for every machine.

Real-time dashboards showing production efficiency, utilization rates, cost per unit, and profitability by product. Executive reports that help you make data-driven decisions.

Operators can record production, report issues, and update job status directly from tablets or smartphones on the shop floor. No more paper forms or delayed data entry.

Most manufacturers are live within 3-4 weeks. We handle product setup, BOM creation, and team training. Your production continues normally during implementation.

Yes. Unlimited BOM levels with support for sub-assemblies, alternative materials, and by-products. Handles the most complex manufacturing scenarios.

FALCON ERP Enterprise Manufacturing supports both. Discrete manufacturing with work orders, continuous process manufacturing with batch production, and everything in between.

Complete integration. MRP generates purchase requisitions automatically. Material consumption updates inventory in real-time. One seamless system from purchase to production to sale.

Our mobile app is designed for shop floor use - simple, intuitive, works on tablets and phones. Operators trained in 30 minutes. Barcode scanning makes data entry instant.

Stop losing money to production inefficiencies and material waste. Book your personalized demo and see how FALCON ERP Enterprise Manufacturing can transform your shop floor in weeks, not months.